Mechanical Interfaces Feedthroughs by Housing Type

Design a hermetic assembly with the ultimate flexibility in materials and conductors.

Product Categories

-

Hermetic Connectors

- Hermetic Bulkhead Connectors

- Hermetic Circuit Board Seals

- Backpotted Connector Assembly

- Hermetic Backpotted Connector

- Custom Hermetic Flange & Plate Assemblies

- Mil-Spec Connectors

- D-sub Connectors

- Micro-D Connectors

- Hermetic Circular Connectors

- Hermetic Rectangular Connectors

- Coaxial Feedthroughs

- M8/M12/M23 Hermetic Connectors

- Push-through Feedthroughs

- USB Feedthroughs

- Electrical Connectors

- Underwater Connectors

-

Wire & Cable Feedthroughs

-

Hermetic Power Feedthroughs

-

Feedthroughs by Housing Type

Locate a Technical Sales Engineer

Douglas Electrical Components manufactures standard and custom hermetic electrical feedthroughs in various housing styles and configurations. Depending on the application, existing hardware, or design constraints, Douglas will partner with you to find the right housing to meet your application demands. With in-house CNC and machine tooling as well as a strong network of outside resources, our team is prepared to support custom designs in competitive lead times while keeping costs down and quality up.

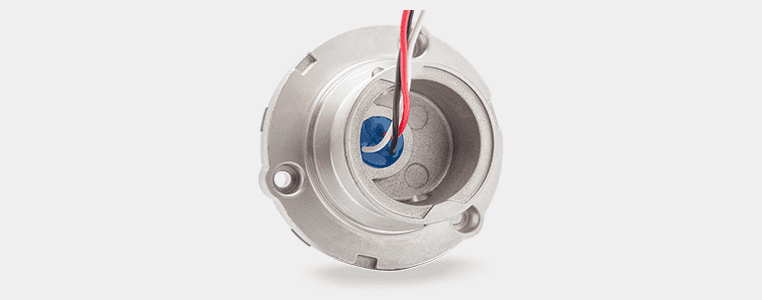

Conflat Feedthroughs

Hermetic CF feedthroughs designed to your electrical connection requirements

Customer-Supplied Housing Feedthroughs

Create lightweight, low-profile hermetic assemblies using your existing housings and hardware.

Face Seal Feedthroughs

Designed for vacuum and positive pressure applications.

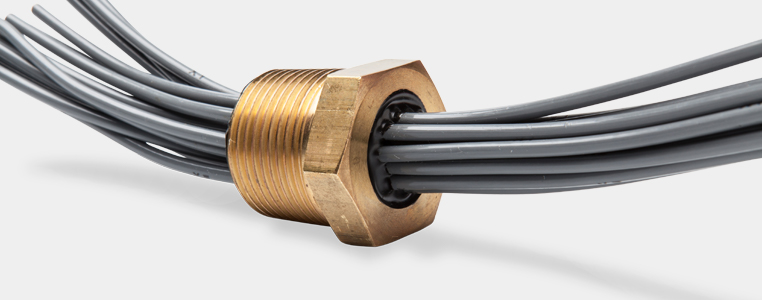

NPT Feedthroughs & Conduit Seals

Stop pouring your own seal and rely on a plug-and-play, reliable solution approved

for hazardous and non-hazardous locations.

KF Feedthroughs

Hermetically seal any electrical conductor or optical fiber in a KF, NW, or QF-type flange.

SAE Feedthroughs

Hermetically seal connectors, wires, cables, terminals, circuits and

optical fiber with an SAE mechanical interface.

Custom Hermetic Flange & Plate Assemblies

Multi-port hermetic assemblies accommodate any feedthrough configuration,

with time and troubleshooting minimized.

Hermetic assemblies are available in a variety of materials from plastic, brass, and aluminum to stainless steel and specialty nickel alloys for more corrosive applications. We have the capability to also use customer-supplied housings to directly cast the electrical connection to hermetically seal it to maintain a low profile, light weight, or seal within complex geometry.

Our high-strength, hermetic epoxy is chemically inert, providing a hermetic seal between any conductor type and the mechanical interface. This includes wires, cables, connectors, printed circuits, flex/rigid circuits, and optical fibers. In the development of a hermetic assembly, incorporating Design for Manufacturing (DFM) principles involves optimizing the design to ensure that the manufacturing process is efficient, cost-effective, and of high quality, leading to a seamless production of the feedthrough while minimizing potential issues and delays. Our team will integrate other electrical components into the design such as shielding, connectors, and cable harnesses directly into the assembly for plug-and-play operation.

Utilizing LEAN manufacturing, our assembly process is designed to support production volumes from single piece orders to hundreds of thousands of pieces. Our feedthroughs and assemblies are manufactured in Randolph, NJ to ISO 9001 standards with IPC-620 trained technicians (AS9102 First Article Inspections available upon request; contact factory).

Locate a Technical Sales Engineer

Features

WHY CHOOSE DOUGLAS?

- Build More – Buy Less – Create high density hermetic solutions using our proprietary epoxy technology to create an air- and moisture-tight seal of virtually any conductor, circuit, or optical fiber.

- Get it Faster – From rapid prototypes to full scale production, Douglas Electrical Components manufactures standard and custom solutions for MIL/Aero applications in our NJ facilities on schedule.

- Plug & Play – With a Design for Manufacturability mindset and technology with ultimate design flexibility, our application engineers will partner with you to design a hermetic solution as a second source or new design to optimize it for your operational success. Save time and money with Douglas Electrical Components.

MARKET CAPABILITIES

- ISO 9001:2015

- ISO 14001:2015

- ITAR DDTC Registration

- UL/cUL 1203, UL 886, UL 674, and UL 913

TECHNICAL ADVANTAGES

- ITAR-, DDTC-, DFARS-, Conflict Materials-, and ROHS-compliant assemblies.

- AS9102 First Article Inspections available upon request; contact factory.

- Transform standard non-hermetic connectors into hermetically sealed assemblies.

- Electrically and hermetically tested to ensure quality.

- IPC-620 certified technicians provide the basic hermetic seal and cable harness work like labeling, bundling, twisting, shielding, filtering, solder, and crimping.

- Chemically compatible with a variety of liquids

and gases - Choose from mechanical interface materials including MIL-certified stainless steel, brass, plated steel, or lightweight options of aluminum, titanium, and plastics

- Use a variety or combination of wire and cable materials, wire conductor types, gauges, and lengths

- Integrate hermetic seals directly into active sensing

elements, circuit boards, and flex circuits to save

weight and space

FAQ

What are some standard housing materials?

Douglas offers a variety of standard housing materials including brass, aluminum, and stainless steel. Additionally, we can machine and hermetically seal plastics, specialty alloys, and more. The material type will depend on the operating conditions such as the pressure and temperature; contact our design engineers to review your application.

How do you test your housings for leaks?

Depending on the fitting and customer requirements, we have two standard tests. First, we offer helium leak testing via mass spectrometer. Second, we can offer pressure testing in-house up to 15,000 PSI for high pressure applications. All assemblies are 100% tested (no lot testing) to ensure each hermetic assembly meets our quality standards. Our in-house machine shop ensures that tooling is developed to properly test and verify each assembly.

How do I calculate the wire density in a feedthrough?

Our standard catalog has some basic information on wire density, yet it is best to contact our team. We will review your requirements and combine the correct wire gauge and conductor count for the housing size to ensure the proper fit, performance, and highest density possible while maintaining all electrical performance properties.

Do you offer hermetic assemblies for explosion-proof applications?

Yes. Our NPT line of hermetic electrical feedthroughs (commonly referred to as conduit seals or wire bushings) are available with approval to Class I Division 1 Explosion-proof. Contact us for ATEX availability as well.

Can the housing be designed with additional features such as integrated shielding or grounding?

Yes. Our technical sales engineers will work with you and your team to integrate connectors, shielding, grounding or any other design features to make the installation process seamless.

How do you address potential issues like outgassing in vacuum or space applications?

Douglas employs a low-outgassing hermetic epoxy to its hermetic electrical feedthroughs and assemblies. Check our Documents tab to download information on outgassing.

Image Library

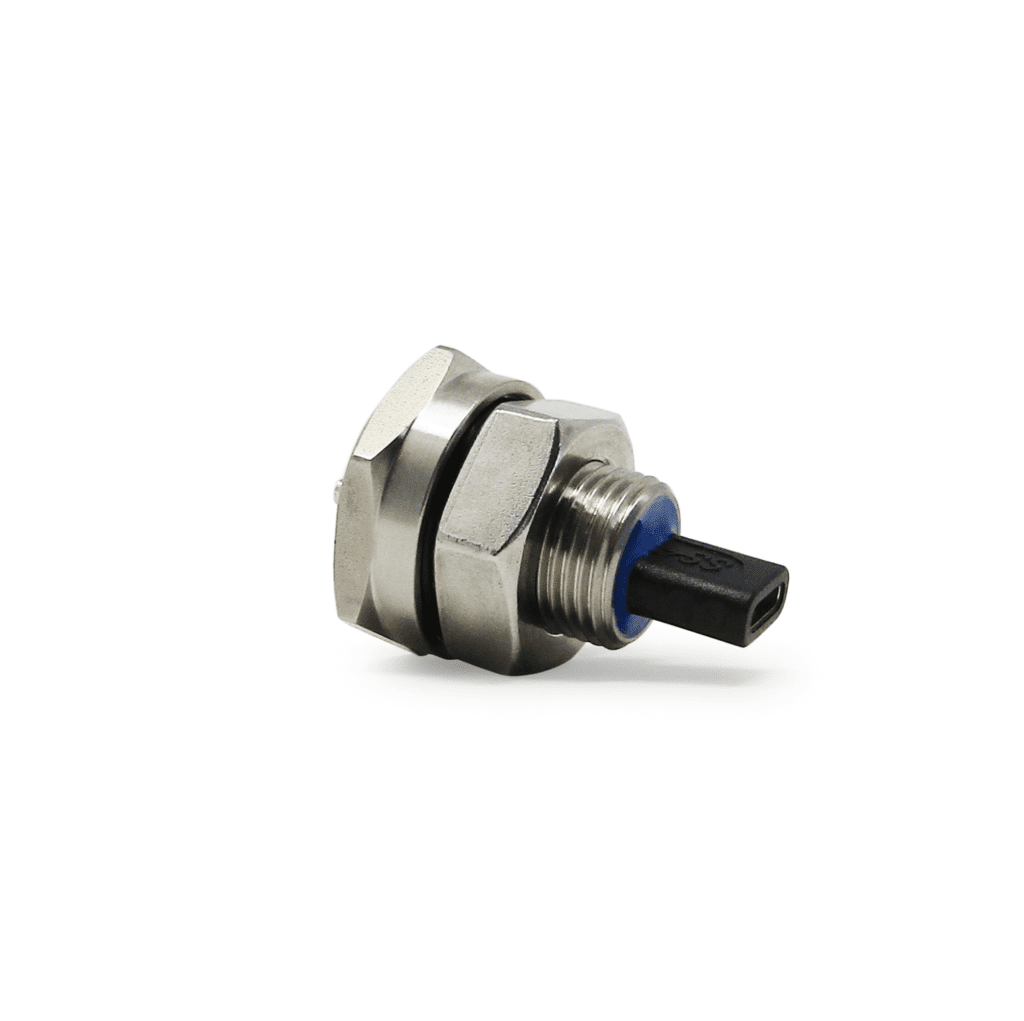

Hermetic USB 3.0 Feedthru

Hermetic USB connector with custom radial O-ring seal for high pressure

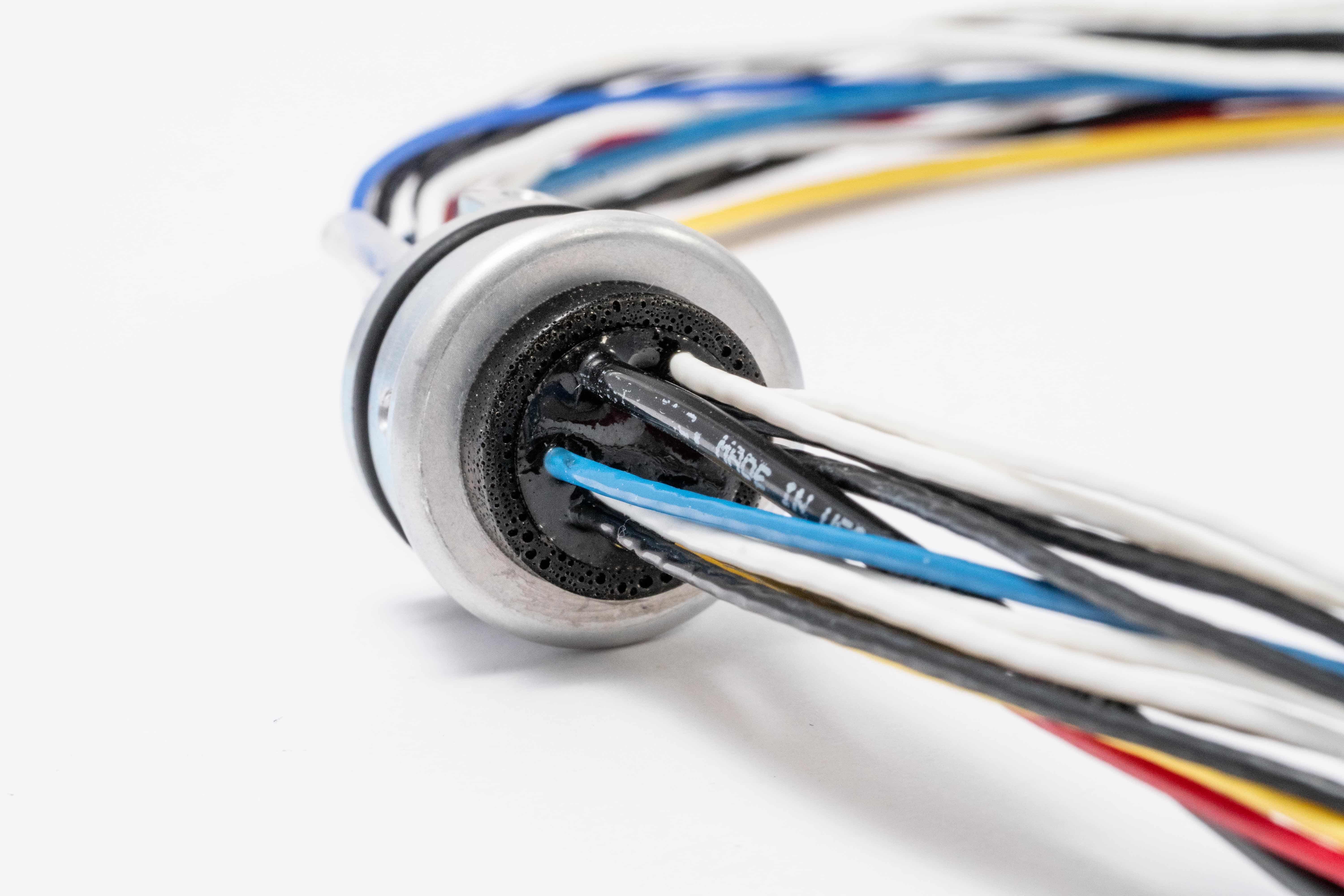

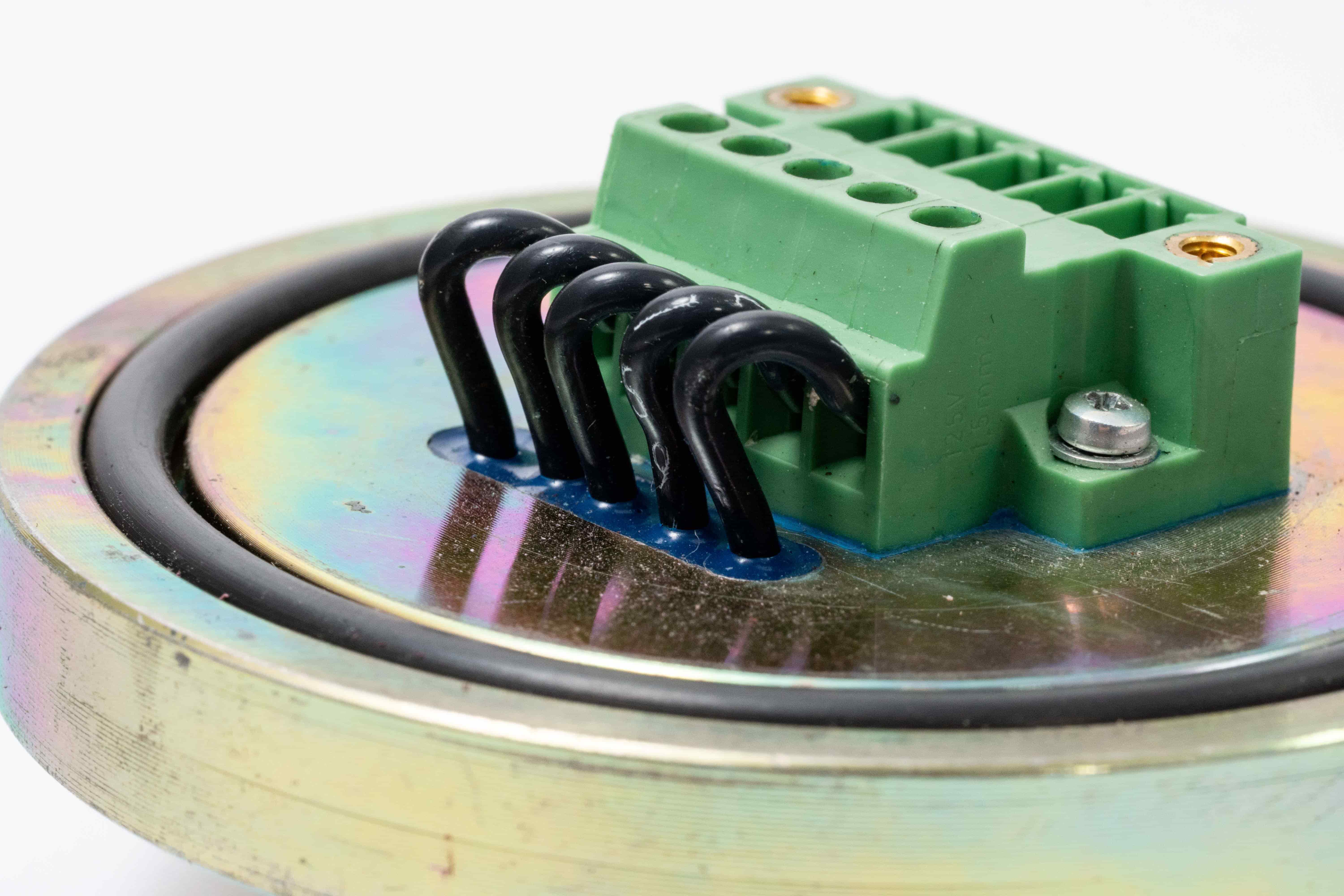

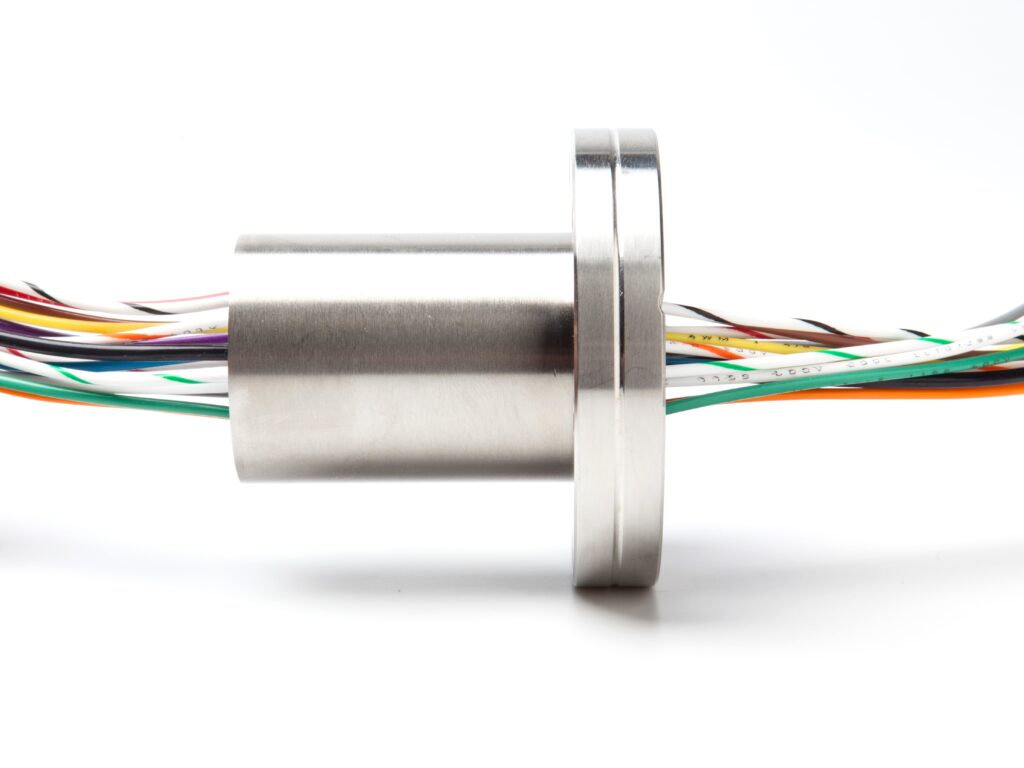

Radial Seal Close-up

Hermetic wire feedthrough with radial o-ring seal

KF Hermetic Fiber Optic Feedthru

Custom KF feedthrough with optical fibers

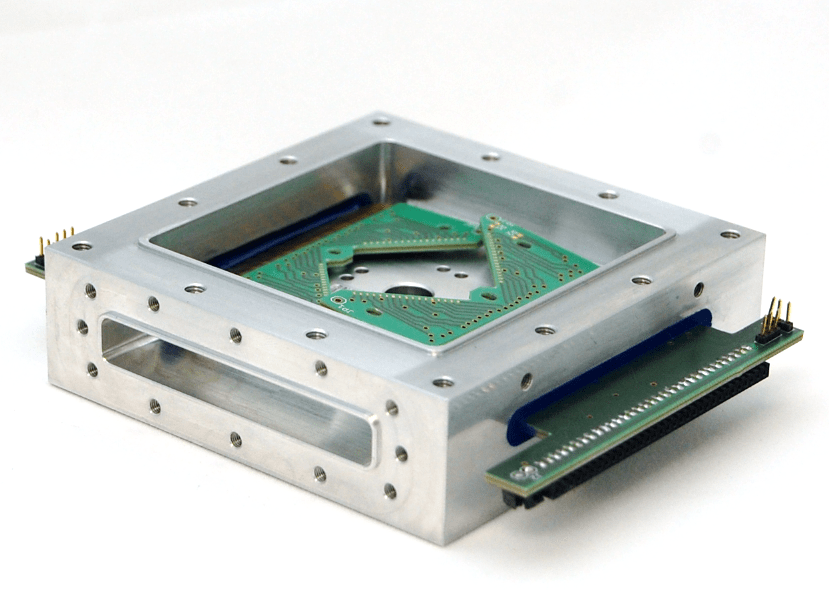

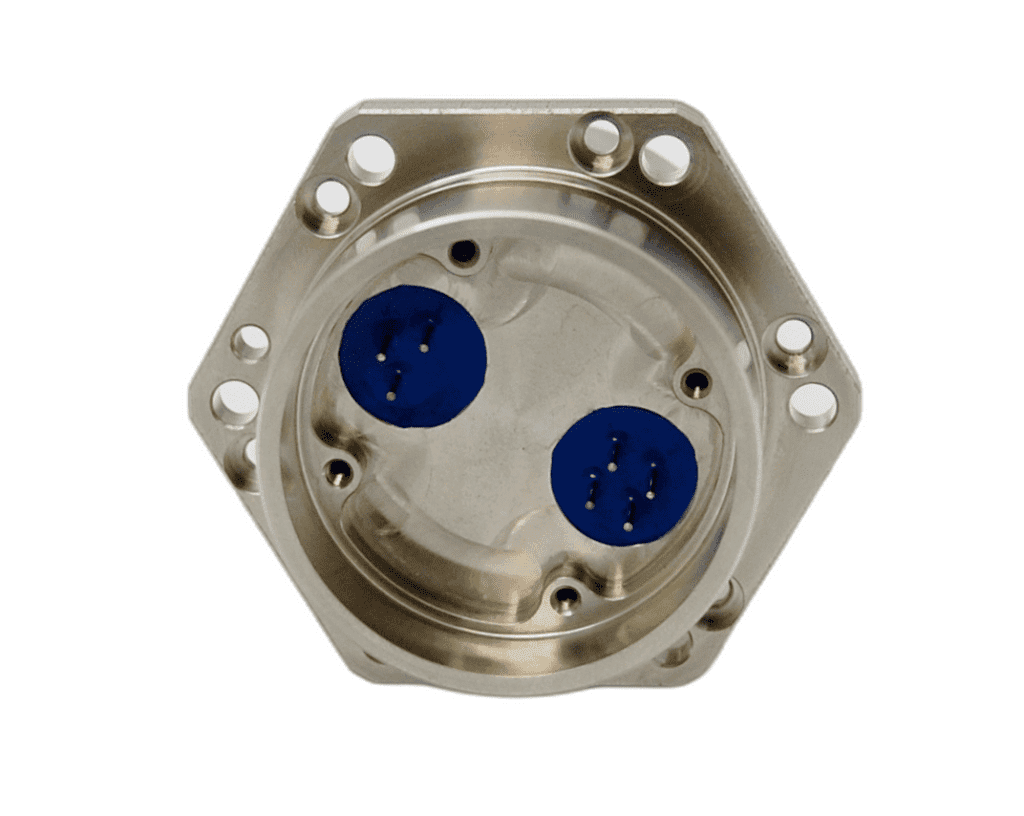

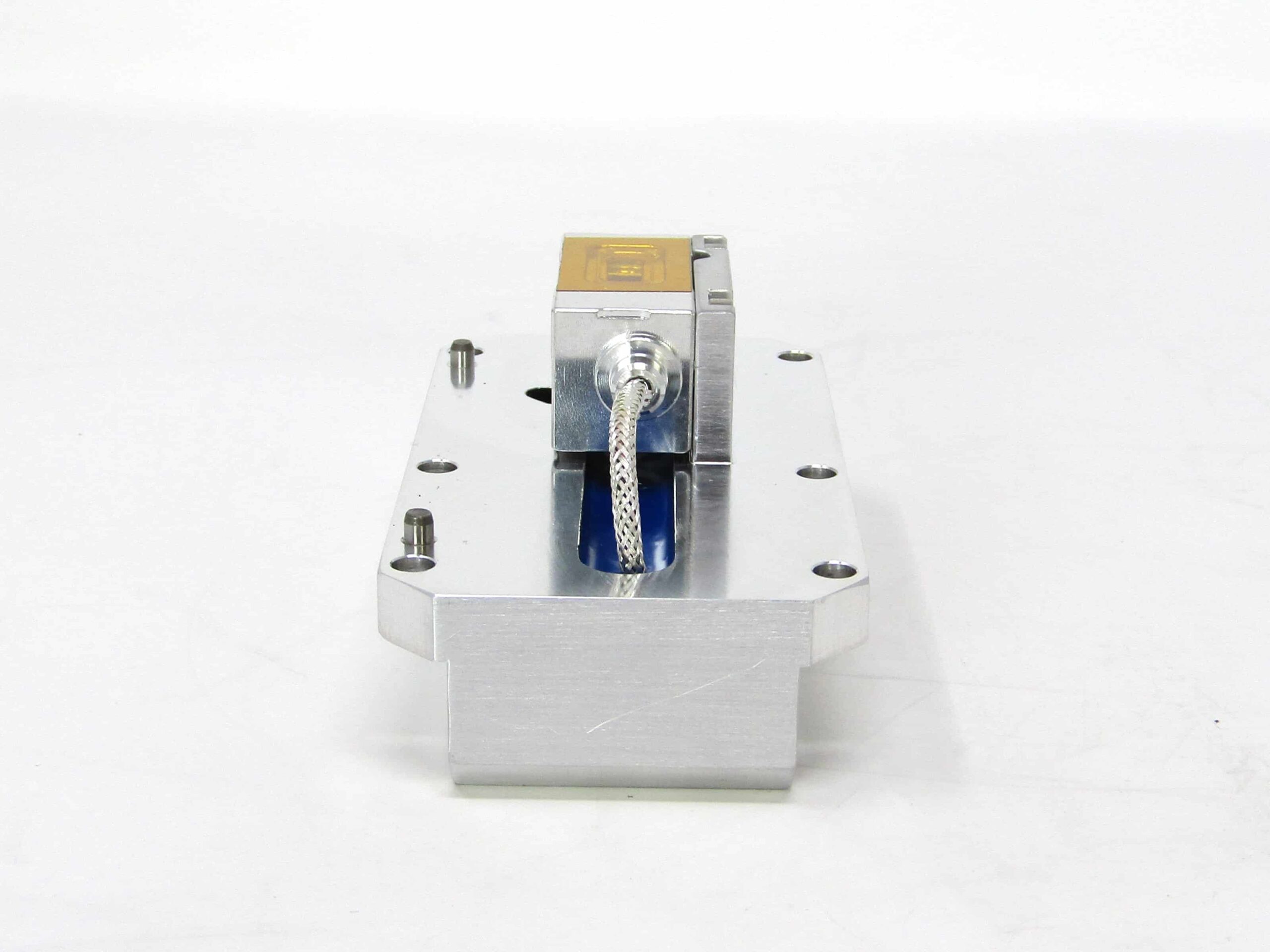

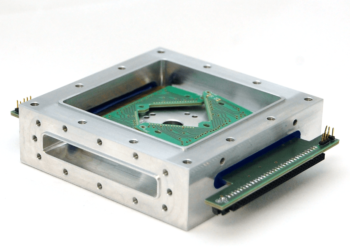

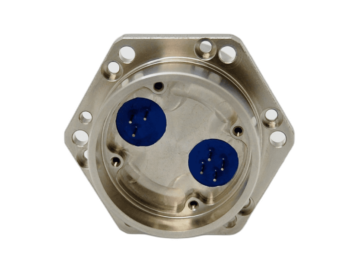

Dual Circuit Seal

Dual circuit hermetically sealed inside custom flange

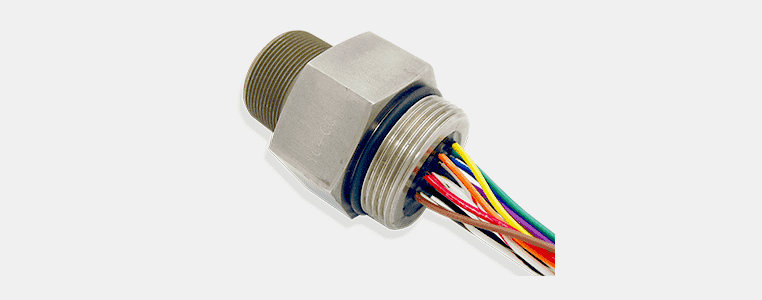

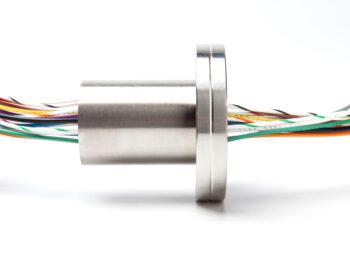

Custom Wire Feedthru

hermetically sealed wires terminated in connector for high pressure applications

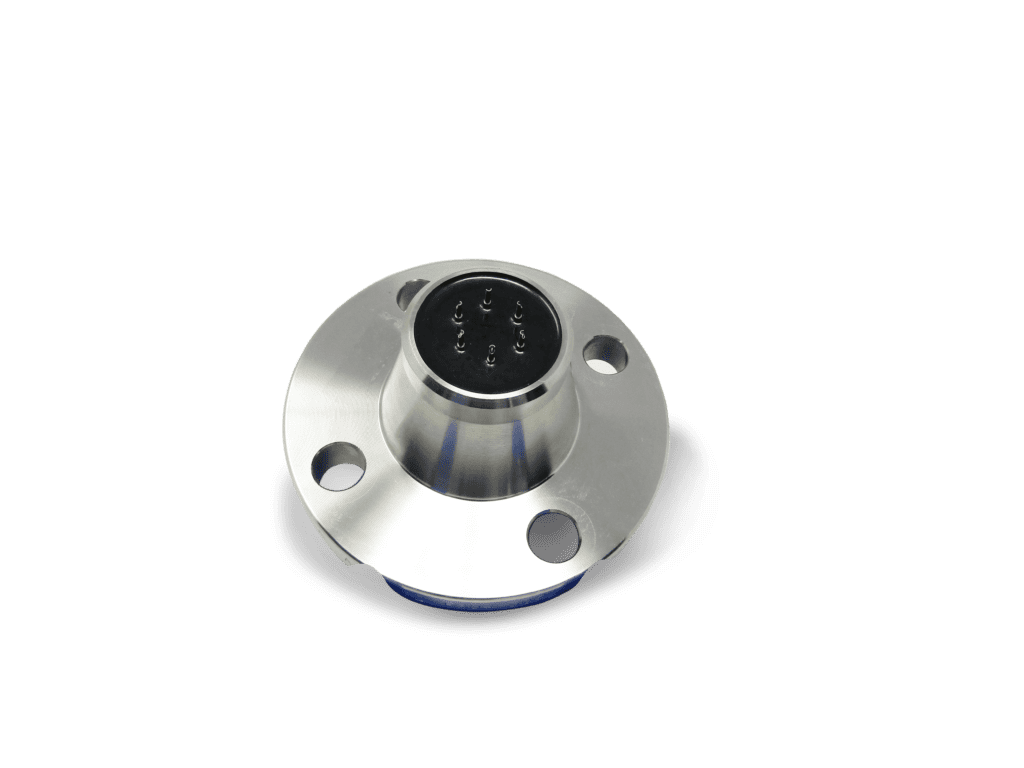

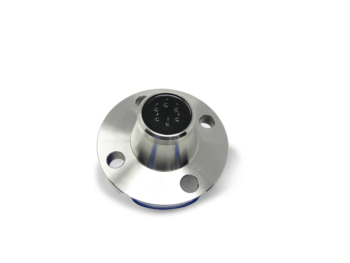

Custom Flange pin sealed

customized flange hermetically sealed with integral pins

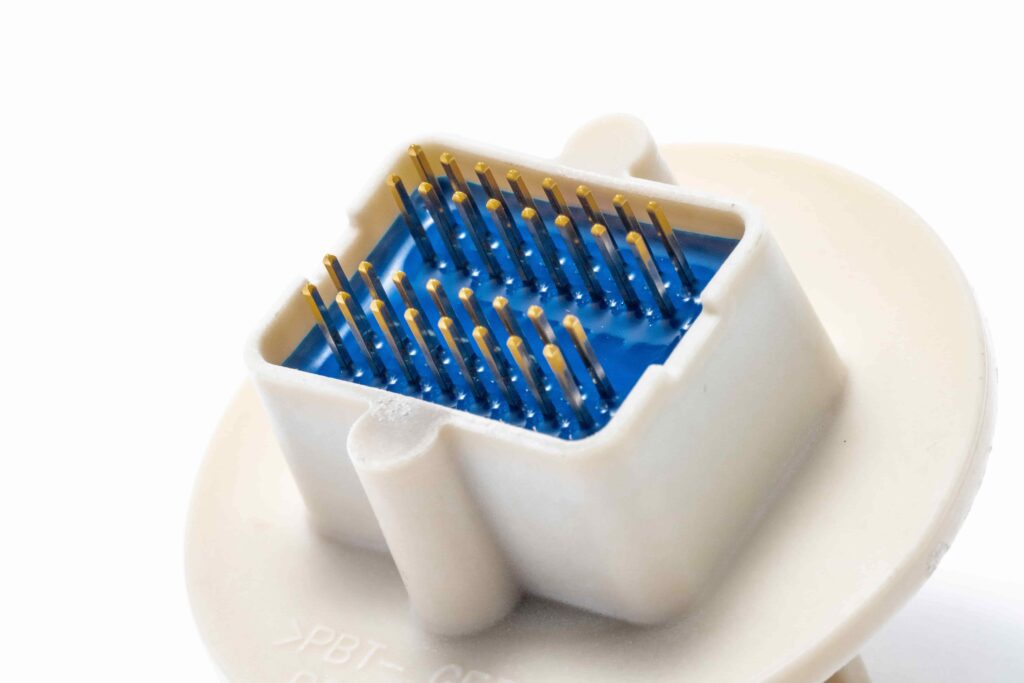

Epoxy-sealed Pins in Custom Housing

Hermetically seal pins within a custom housing.

Portplate rectangular, wire feedthrough

Hermetically Sealed Plastic Connector

customized plastic connector with integral pins for pressure application

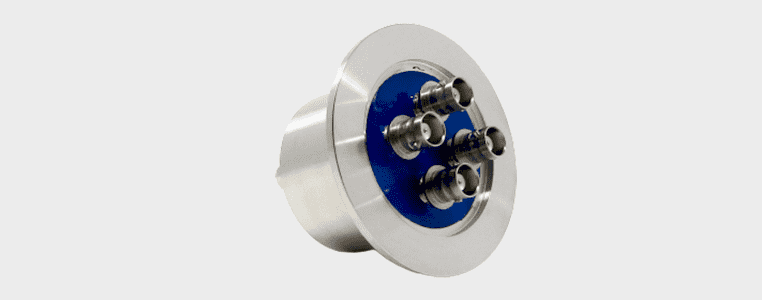

Hermetic SMA Coaxial Feedthru

Hermetic SMA coaxial feedthrough with vacuum face seal interfaces and four connections

Hermetic MTP Fiber Optic Feedthru

Hermetic optical fiber feedthrough with MTP connectors and vacuum face seal

CF Feedthrough with RJ45 and D-sub connectors

Vacuum view of CF hermetic feedthrough featuring RJ-45 and D-sub connectors

Dual USB Hermetic Feedthrough with KF flange

Hermetic USB feedthrough with two USB-A connectors in KF type flange

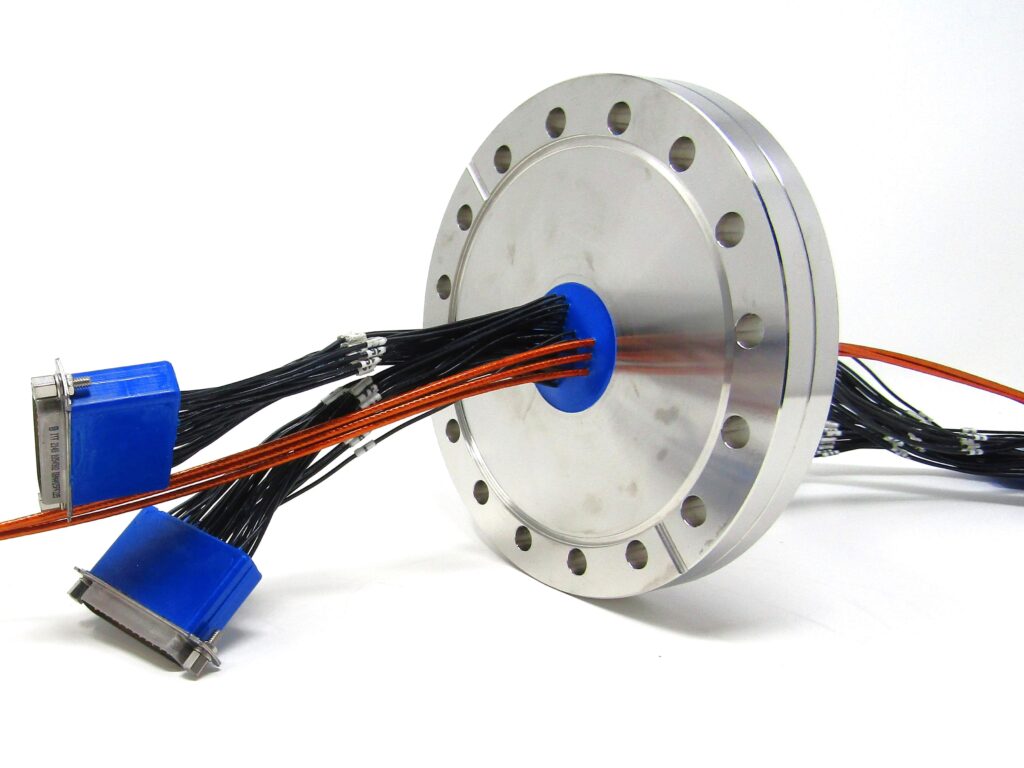

Multi-conductor type CF Feedthru

Hermetic CF wire and thermocouple wire feedthrough with integral connectors

CF Feedthru Side View

Side view of a hermetic electrical feedthrough with CF Flange

CF hermetic feedthrough with milspec connector

CF hermetic feedthrough with MIL-spec connector

D-sub & RJ45 CF Feedthrough

CF electrical feedthrough with D-sub and RJ45 ethernet connectors

Hermetic NPT Wire bushing

Explosion-proof rated wire bushing with brass fitting and labeled conductors

NPT Fiber Optic Wire Bushing

Fiber optic NPT threaded electrical feedthrough conduit seal

Hermetic NPT feedthrough with push/pull connector

Hermetic NPT electrical feedthrough with push/pull connector provides a compact footprint with inexpensive sealing method.

Automotive Hermetic Wire Harness

hermetically sealed automotive wire seal with integral connectors for plug-and-play install

CF Wire Feedthrough

Hermetic wire feedthrough with customer-specified conductors

Hermetic Bulkhead SMA Feedthrough

Hermetically seal multiple SMA connections in a single vacuum face seal assembly

Compact Hermetic USB Assembly

USB-C hermetic bulkhead connector with small jamnut design

USB Wire and Connector Feedthroughs

Hermetically seal USB connections with wire or connector interfaces for vacuum and pressure applications

hermetic bulkhead hdmi-feedthrough side

Hermetic bulkhead HDMI-feedthrough is designed with a face seal to simplify installation and transmit signal in vacuum or positive pressure.

15 position Hermetic Micro-D reversible hermetic feedthrough angled pin view

15 position Hermetic Micro-D reversible hermetic feedthrough angled pin view

Dual D-sub Hermetic Connector

PotCon Dual sub-D hermetic connector on rectangular flange creates a higher density connection with a single penetration point.

RBTW custom d-sub seal in customer housing

RBTW custom d-sub hermetic seal with integral wires. The hermetic connection is installed in a customer designed and supplied housing.

Custom Housing Feedthru

Custom feedthrough design for high vacuum applications

Hermetic 38999 Assembly Side View

Create a customized hermetic seal for pressure applications

Multi-flex hermetic feedthrough

Multi-flex hermetic feedthrough circuit with face seal housing and jam nut

Documents & Downloads

Literature

Datasheets

Whitepapers

Material Data

Certificates & Standards

UL 1203 Explosion-Proof and Dust-Ignition-Proof Electrical Equipment for Use in Hazardous (Classified) Locations